As with most redesigns of either a part or assembly you never know if the redesign worked properly until you have used it for some time. This has been the case of my filament sensor assembly for my Creality CR-10 S4 3D printer. One thing that always bugged me from the start was this sensor that constantly got vibrated off of it's mounting location due to it's poor design. Here is how it all started back in September of 2018 while running my printer.

This is what the original sensor assembly looked like that came on my Creality CR-10-S4 3D printer. The small box on the left of the assembly houses a small circuit board with a contact switch that activates once the filament runs out after passing through the sensor and then triggering the switch to halt the machine so you can reload a new spool of filament to continue your project.

The only problem with this setup was the attachment of this assembly to the printer itself. It simply was slid on to a flat plate near the stepper motor that pulls the printer filament into the machine to make your part. This sensor over time would vibrate off of the mounting plated and be left dangling while the part continued printing. Not something I thought was a good idea.

So with the first revision of the sensor assembly I eliminated the small part that slid on to the mounting plate and made a more solid mount that bolted directly to the machine through the mounting holes that held the guide wheels for the left side of the printer "Z" axis. In the images above you can see the assembled sensor assembly as well as the exploded view of the same assembly.

Just below the blue top cover plate is the sensor circuit board that make this assembly actually work. Just a simple on/off switch that comes on when the filament runs out. This assembly mounted perfectly to my 3D printer but had a flaw in the design and I put off correctly it until yesterday.

The problem with this setup was that it was difficult to install new filament through this assembly and have it also be fed easily into the stepper motor drive assembly at the same time. It seemed at times to have no issues and other times I would fuss with it for 10 minutes or more to get new filament loaded into the printer. An issue that had become more and more frustrating while trying to 3D print parts.

What was going on was that the original mount made loading new filament into the machine simple because the sensor could be removed from the printer first. Then new filament was passed through it's opening and then on to the stepper motor drive assembly opening. Once this was accomplished all that was needed to be done was remount the sensor assembly and printing could continue on before the reload was needed. But this just put everything back the way it was where the filament sensor would eventually vibrate off of the printer once again over time.

To finally eliminate the bad part of the first redesign I had to make the modification just a bit more user friendly. In the image above you can see the first redesign on the left and the second redesign on the right. On the left redesign the yellow column is mounted to the 3D printer along with the sensor switch, blue cover plate, three mounting screws and the larger bolts and nuts to hold the assembly to the 3D printer. Again this looked good but made it difficult to reload new filament as it could not be removed from the machine while trying to put in new filament.

On the right you can see the new improved filament sensor assembly. In this assembly you can see the redesigned yellow sensor mount, four neodymium magnets, a red sensor mounting housing, the sensor circuit board, the blue circuit board cover plate, three cover plate screws, and the large mounting bolts, nuts and spacers for the complete assembly.

This new assembly now has a solid mount as before and the capability to remove the sensor from the assembly quickly and easily because of the small magnets between the upper and lower sections of the assembly.

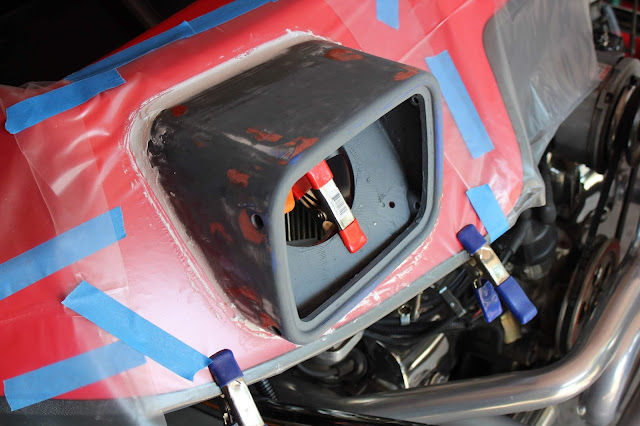

In the photo above you can see the new assembly mounted on to the 3D printer. The white arrow is pointing to the filament out sensor, the orange arrow to the stepper motor that moves the filament into the printer, and the green arrow shows the upper mounting bolt that holds the top portion of the lower assembly firmly in place.

The new magnetic mounts for the filament sensor are strong enough to hold the sensor in position while 3D printing but not so strong that it makes it difficult to pull the switch off of it's mount while reloading the machine with a new spool of filament.

I think this will be the perfect solution to the problem that I was having with my first redesign. As I said from the start sometimes you have to use the new design for a while to make sure it is what is needed to fix the original problem with a design. In my case I ended up finding an additional problem simply because I could nto remove the sensor while loading new filament into the printer.

I will use the new setup for awhile to make sure I have everything ironed out the way I want. If not then I will try again but for right now this looks to be the best solution to the original issue as well as the found issue I was having with the filament sensor. At least I hope so anyway. Time will tell.