This last fall as usual like most guys that take care of chores around the house I had to once again drag my aluminum extension ladder out of the garage to clean the gutters. Not a terrible task on my part as I take precautions to keep leaves out of my gutters in the first place by using gutter guards. But this only eliminates around 80-85% of the problem. So I still have to check the gutters to clean out whatever I can find that manages to sneak into the gutter even with using gutter guards. It's not the gutter guards that I have a problem with. It's the task of just dragging the ladder out in the first place.

My step ladder is great! It can extend out to be an extension ladder. It can be adjustable to easily be used on a set of stairs. It can even come apart and be used as two ladders so that a platform can be put between them. It is a very strong, solid aluminum construction that will last a lifetime. All good things. The bad thing is that this ladder is heavy. Forty-two pounds heavy. I am not a big guy that bench presses Chevys on my weekends so to lug out a 42 pound ladder in my eyes is to but it simply....a pain. With that in mind another project was born to eliminate this task and save my back in the process.

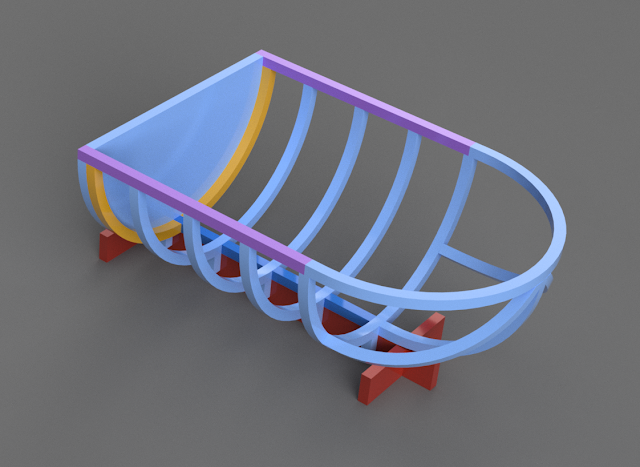

Why not have wheels on the ladder so that I could roll it outside when I needed it and not have to pick up this thing that is taller than I am in the first place? Shown above is what I came up with. I once again laid out the design using Fusion 360 CAD software (free by the way online) to get all of the parts I needed designed for the project work out. The image above shows the parts in various colors just so it would be easier to see all the different components.

On the bottom of the ladder is a plastic foot that sits on the ground level when it is used as a step ladder. This foot is only held in place using a single 1/4" bolt. This worked out perfectly for my design as the framework of the wheel assembly needed to be mounted to the ladder and this mounting hole for the foot fit the bill.

Inside of the wheel assembly is one of three mounting blocks (shown in red). This is held in place using a 1/4-20 bolt 2.5" long and running through the outer wheel plates (shown in yellow) to keep the wheel assembly from moving up or down on the ladder arm. Then there are two more outer mounting blocks that again are mounted between the outer wheel plates and are on the outside of the ladder arm to keep the assembly from spinning. Lastly the wheel that makes it all work that I found online needed to have a rounded shape as the ladder arms tip outward at the base at 7 degrees. A flat shaped wheel would be riding on it's edge so a rounded shape was called for. I found what I needed by using 4" diameter inline skate wheels.

I started doing some calculations on the design and figured out that the ladder when you pick it up weighs 42 pounds. But if you only pick up one end of it the weight you have to carry is only 21 pounds. So it only goes to show that each wheel only needs to carry 10.5 pounds each. I original was thinking that I would have to make the wheel plates on the outside of the assemblies in aluminum. I did some test parts and decided to just 3D print the entire assembly similar to what a bridge would be built like.

Also when I 3D print parts I adjust the amount of fill I have inside the part along with the number of layers to construct it. So if you had an egg and the shell was one layer thick to make it stronger you make more layers. This is what I did here on this assembly. Instead of my usual two layers I beefed it up to four layers thick and instead of making it hollow (no fill at all) I filled it at 40% fill. This make the parts very solid and with the light load I think the assembly will do the job I designed it for rather nicely.

This is what I normally look like when I try to pick up my step ladder. Even using both hands the expression on my face is not much different than the one you see here. (Maybe not as extreme but you get the idea).

Here I'm a much happier camper! One handed and I'm still smiling! Eliminating 20+ pounds helps a lot. Plus the fact that now I can just roll the ladder wherever I want effortlessly! A win-win in my book any day.

I was not sure that the 4" wheels would be big enough to do the job but then again I did not want to make the wheels to large either just to make storage any more difficult in the process. I will keep an eye on the wear and tear that the wheel assemblies take over time just as a precaution.

Once I did bolt everything on to my ladder the wheel assemblies stiffened up very nicely so I think the design will do it's job as planned.

By the way the ladder wheel assembly is only used to roll the ladder from place to place. You never step on the ladder with the wheels supporting it. It's designed not to be able to work that way. When the ladder is used as normal the wheels do not even touch the ground. This eliminates the chance that the ladder would roll out of place and at the least have the wheel assembly break apart because of the extra weight if you stepped on the ladder when using it. The smile on my face will increase over the years as I use this newly designed attachment to eliminate or at least lighten the load so to speak of a back breaking chore.