As most of you already know I purchased a rather flashy looking little dune buggy shortly before Christmas. I have been getting all of the paperwork done to get it licensed, registered, and insured so I am happy that all of that work is done. I still have a couple more projects planned for the dune buggy and one of them is to add a glove compartment to it. Currently it does not have one so I thought it would be a good thing to add to the car just to store my registration papers along with sun glasses and maybe some sun tan lotion for the summer sun.

Here's another chance for me to show off my little beauty once again so that if you have not already seen it on my blog before now's your chance.

Here's a good shot of the interior of the buggy and as you can see there is a rather large looking void in the right side of the dash where a glove compartment would normally be in any other car. In this photo the space for the glove compartment looks huge but in reality it is about average size. The big trick to getting a glove compartment made was trying to figure out the exact shape needed to fill this void in the dash as closely as possible so it would look right in the car.

Here you can see the nice rounded shape of the dash that is just ahead of the passenger. The roll cage cross member that is horizontally mounted and is under the gauges in the dash looks just a bit out of place with no glove compartment so I started scratching my head to try and figure out the best plan of attack to make a glove compartment fit into this odd shape.

I started with a piece of foam core that I had in my work room and cut out a shape the I thought would fit nicely as the base for the compartment and line up fairly well with the lower shape of the dash. I taped this piece in place with masking tape to hold it where I needed it while again trying to figure out the rest of the compartment. On the right side of the roll cage is a mounting plate with a bolt running through it and this had to be cleared when inserting the base plate made of foam core. Another obstacle to get around for the glove compartment.

I next added 1/4" Styrofoam strips to the rear edge of the base plate foam core. I hot glued these in place to one another as I did not want to get any hot glue on the dash itself. Next I taped down an upper foam strip where I wanted the glove compartment to be at it's highest. Then I started adding more foam strips between the upper and lower horizontal strips and hot glued these together. The reason for the strips was so that I could get an accurate profile of the original dash to make a mold for the new fiber glass glove compartment later on in the project.

Here all of the vertical Styrofoam strips have been installed and hot glued to each other. Again no gluing was done directly on to the original dash as I did not want to cause any damage to the anything and this entire assembly needed to be removed in one piece.

To complete the shape of the glove compartment I added several triangular foam core pieces on both ends of the enclosure. These pieces took me a little time to get correct as the back surface of the triangles needed to be curved to match the shape of the new compartment. Again as before I hot glued these in place.

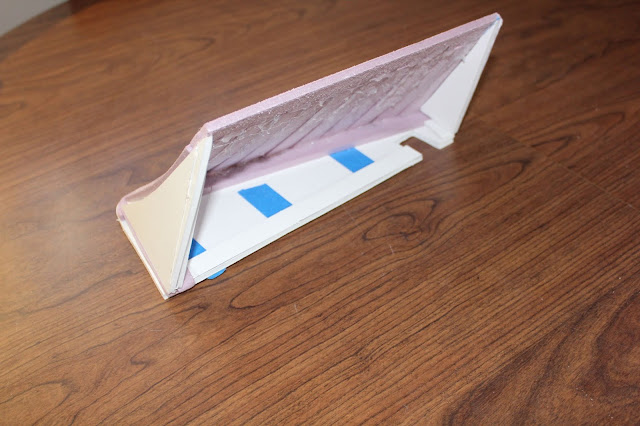

With all of the foam pieces and foam core hot glued together I was able to pull the entire assembly for the glove compartment out in under a second. So I was happy that it came out so easily and fit perfectly into the cavity in the dash. As you can see the shape of the glove compartment is at this point looking rather small and very odd shaped. But at least I have the general shape at this point so I can proceed to figure out the next steps in the project.

Here I've added a piece of foam core just to get and idea of how the door would be attached to the glove compartment. You can see a cut out in the lower right corner of the compartment and this as I said earlier is needed to avoid hitting the mounting hardware that is used in the roll cage assembly.

At this point in the project I knew that I wanted to have a lock for the glove compartment. I tracked down an original compartment lock for an original 60's era VW. This only cost me $17 with free shipping and was the perfect lock for the project. Very small and brand new at that.

I knew that I did not want the door striker plate for the lock to be made out of plastic as this much sooner or later would wear out and have to be replaced. So I came up with this little striker made out of a small piece of aluminum that was in my supply of parts in the shop. As you can see it is not very large. This I mounted to an adjustable bracket for the striker assembly.

This was the first design I came up with for the face of the glove compartment. As you can see I did not have the correct lock at this point and have the cutout for the roll cage mount. This caused several issue with the glove compartment as it made the door smaller and you could see hardware on the face of the door frame. On top of all of this the shape of the Styrofoam and foam core (plug?) came to a rather tight angle at the top of the compartment which left very little room for the lock to work at all. Something had to change.

The only choice I had to keep the project moving forward was to extend the glove compartment out one inch to make room for the lock and the striker. This gave me a roomier glove compartment and the needed space to make the lock and door striker work properly. I also was able to eliminate a bunch of bolts for the door frame. This cleaned up things nicely for the look of the compartment as well as giving me a larger door opening. The recessed bolts that hold the hinge mounting hardware will be bonded into the door when it comes time to do the finishing work on the project. This will make the glove compartment more secure as well.

Here's a good look at the door and door frame assembly with the door lock and striker installed. The blue pieces mounted to the inside of door are retaining clips that hold 1/4" aluminum pins that are used as hinges for the door. The tabs that stick out of these clips on both sides of the door are there to keep the door from opening to far when it is unlocked for use. The door will only rotate from vertical to horizontal a total of 90 degrees. A simple and effective way to hold the door in place and in position.

Here's a nice look at what the door assembly will look like from the outside. Again the recessed bolts will be bonded into the door which will make them more secure, better looking and become permanent studs for the hinge pin retaining clips.

Here's a good look at the hinge pins that will be mounted in the door frame. These pins as I said earlier will hold the door in place with the help of the hinge pin retaining clips. This setup also makes it easier to install the door or remove it if it becomes necessary in the future.

With the design finally sorted out I went ahead and added the addition one inch of Styrofoam to the Styrofoam and foamcore plug. Then I sanded it into shape, rechecked that it still fit into the dune buggy properly, wrapped it in clear packaging tape and then fiber glassed only the top surfaces as shown in the photos above. I wanted to be able to get the foam plug out of the fiber glass so I left the bottom open for easier access in this portion of the build. With the clear packaging tape on the outer surface of the plug it would give me a nice smooth finish on the inside of the fiber glass part and also make it easier to remove the new compartment from the plug.

After I let the fiber glass cure overnight I was able pop the new fiber glass compartment off of the plug in less than five minutes. I used some popsicle sticks to pry the fiber glass loose from the plug and tapped it with a rubber mallet to release the upper portion of the new part. I now had a new fiber glass housing for the glove compartment that fits perfectly into the dune buggy and was nice and smooth on the inside as well.

I took a Dremel tool and cut out the front area of the housing where the door frame for the compartment would be mounted. I did not need to add any additional fiber glass to the interior of the compartment as it was plenty stiff enough at this point.

To make the bottom of the compartment I took a piece of one inch Styrofoam and fiber glassed the top surface with six or seven layers of 8 oz. fiber glass cloth. This gave me a nice stiff section to work with for the base of the compartment. I removed the Styrofoam and then sanded the new panel smooth. I then took fiber glass resin and micro-balloons to make a putty mixture to join these two pieces together.

To finish of the compartment I next added the door frame that I 3D printed a couple of days earlier. This slid into place very nicely. I bonded this to the fiber glass compartment after having marked and trimmed the front lower fiber glass surface. It was simpler to remove this portion of the fiber glass before I added the door frame. I did not want to mess up the door frame after it was installed.

That's about it for this post. Once I get the door 3D printed I will be able to put all of the rest of the parts together for the compartment and work on the mounting hardware that will need to be created to install it into the dune buggy. When I get all of that figured out then I will take the compartment out of the car, tear it apart and prep it for primer and paint. So lots to do yet. I'll fill you in when I get farther along. Have a good day in your shop!

Hello Dave,

ReplyDeleteDo you still have the velomobile?

Regards,

-George

I had some questions about your velo. Would you be willing to e-mail me at gberka57@comcast.net?

ReplyDeleteThank you,

-George

It was great seeing the step by step progress of the glove box you were getting together. This was really interesting to see all the incredible work that you did and information you shared. Have a good one.

ReplyDeleteLawyer