A lot of times while working on projects here at the Tinker's Workshop I find bits and pieces of equipment that I've collected over the years and thought someday I could use this for something. This is the case with today's project. Years ago when I was still shooting photos using a film camera I had my own darkroom to develop my pictures. As I said this was years ago and I no longer use film cameras as most people do now a days and so I stopped developing film and moved on. I came across a lens for the enlarger that has been floating around my workshop for some time as it makes a nice eye piece to look at something really close up. Similar to the eyepiece a jeweler would use to fix a broken watch. So I kept the lens and it has severed me well over the years. Putting two and two together I thought why not make an adapter for the lens so that I could use it with my iPad and then I could take photos of what I see. So that is the project for today.

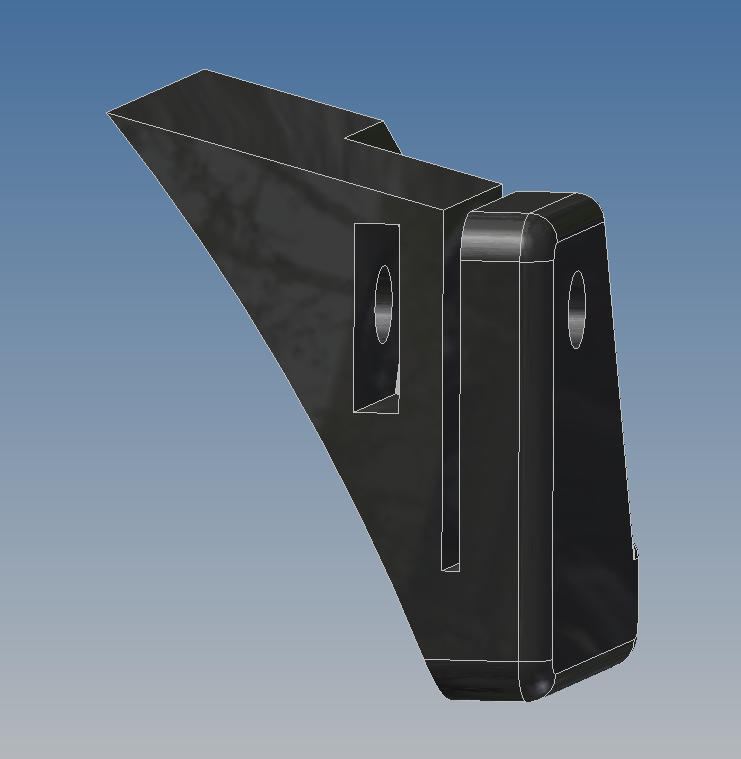

As I usually do I started with my computer design software to get the rough shape that I needed for the project. This little box like object is the adapter that will fit on to the iPad and make the lens work with the camera. The trick with this portion of the build was just to get the lens opening that you see here, the right size for the threads on the lens from the enlarger. The opening is only around 1.5 inches in diameter and so I had to make two or three test parts to get the hole just the right size so the lens could be screwed into the opening or make it at least a friction fit. I would not want the lens to fall out when I wanted to use it. Also the slot in the adapter needed to be the right size so that it would slide on to the iPad and also stay put. I have a protective cover on my iPad to keep it from getting damaged and so I needed to allow for this extra thickness while making more test parts for this opening as well.

My 3D printer did it's usual wonderful thing and created this slick looking adapter for the little lens that you see here.

After several test parts were made the lens and hole in the adapter were a perfect match. As you can see the lens and adapter fit well together and the set up looks good too.

The adapter is slide on to the upper corner of my iPad here in this photo. You can see the protective outer case that I use on my iPad in this photo as well. The lens at this point is aligned with the camera that is built into the iPad. This alignment needed to be just right and so it too took several more test parts to get it made correctly.

This is what I see on the iPad when I am ready to take a photo. I could have used an assistant with this photo as I need to hold the little Lego man in front of the lens, focus the camera and shoot it too. Thank goodness that I had the iPad on my tripod to at least hold that still for this shot.

To give you a better idea of what a difference this little lens makes to take macro photos I shot this photo first without the lens on the iPad. This photo above is the closest and clearest photo I can take with just the standard lens. Not good at all. Fuzzy to say the least.

Now this is the same shot using the new lens and adapter that I just put together. Quite a difference don't you think. The photo does have it's draw backs as you can see simply because it now is black on the outside and circular in the center of the photo.

Here's and even better shot using the new lens. I like the fact that it is so nice and clear and the detail is so good that you can even see my finger prints in the photo.

The final step in the process of getting the shot that I wanted was just a matter of doing a bit of cropping of the photo to remove the circular view and the black around the outside of the image. This is pretty cool considering I'm using an old discarded enlarger lens and less than a dollars worth of plastic from my 3D printer. A tinker's project for sure. Well worth the time and money to put together. Enjoy the photos.