This past summer a good friend of mine and I had a major project to tackle for my house and the workshop. When my house was constructed the garage was not designed into the house plan but was added years later. Why this was done this way? Who knows. Could have been lack of money or simply it was never thought of. In the process of adding the attached garage an inner stairway was never added to the addition. Again why would you not have an entry way from the attached garage to the inside of the house? I had to pull the car in the garage in bad weather and then go back outside to get into the house. A poor plan at best. Again I suspect it was a lack of planning or money or both.

The floor of the garage does not match the height of the main floor of the house or the floor of the basement so a new stairway was installed to at least get into the house and go up to the main floor. I wanted access from the garage also to the basement at the same entrance. Garry (my house guy and good friend) sat down with me and showed me how messed up the living room would be if I tried to have both the upstairs and downstairs access. It looked to be impossible without tearing up half of the house in the process and probably tripling my cost to get an my new entrance to the house. So that brings me to this project that I can say is or will be completed in the next few days.

Rather than make an additional basement stairway for just moving large supplies easily into the workshop I compromised and instead installed a removable access panel to do the same thing at a much cheaper cost.

Here is the new entrance to the inside of the house after the construction was done. After six weeks of work and a lot of dust that project was completed and worth every cent to get it put in.

Here are the new steps that I now use every day. With a big smile on my face every time there is bad weather outside.

This framed up portion of the wall at the base of the step is where this project that I really want to show you today was started. The wall looks a little out of place simply because it has a frame around it. But this is where it all starts to make sense.

In the basement where there was no room for a complete stairway Garry and I decided to include a hidden removable access panel. As you can see from the panel it is made from a four foot square piece of pink Styrofoam.

To hold the light weight panel in place I made four t-handles that slide into place near the four corners of the panel. They can quickly be installed or removed and hold everything in place nicely.

A four foot square two inch thick sheet of Styrofoam was inserted into a wooden frame and then fiber glassed into place. This sealed the foam to make it nice and strong and able to last for years without damaging the panel. The face of this panel was painted green to match the wall color in the stairway to the upstairs of my house. Again being fiberglass this panel is very light weight and the Styrofoam insulates the basement from any cold air that may get in when the garage door and inner stairway door are open at the same time.

Now with the panel removed I can easily move large pieces of lumber or 4 x 8 sheets of plywood into the workshop with no problem. While doing the stairway construction we used this access port a lot to use the tools in the workshop or pass materials up or down the stairs. The only problem with this access port is that the garage floor is 31 inches above the basement floor. And after jumping up or down from this height while the stairs was being put it I knew that a small stair step needed to be installed to complete this project and make things easier and a lot safer to use.

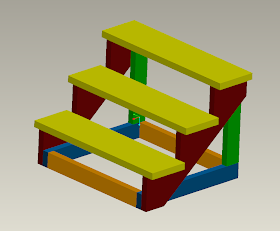

I started designing the small stairs as usual in my computer using my CAD software to figure out just how big they should be. As I said earlier the height of the garage floor from the basement floor is 31 inches so this gave me a starting point. I worked out the details of this little project and then was ready to start putting it all together.

So here in the shop the new little stairway is under construction. I started out with just a simple 2 x 4 frame that is screwed together using pocked holes to hold everything nice and tight. You can see one of the stringers for the steps sitting next to this framework on the table.

The stringers took some figuring out how to lay out on the 2 x 10's but with a lot of head scratching and careful measuring and cutting I got it all worked out. The stringers after cutting lined up perfectly with the simple framework that I started with and only need to be screwed into place to hold them securely to this frame.

Next was just a matter of screwing the stair treads to the stringers. Again I used pocket holes that were put into the stringers themselves. The screws then went through the stringers and then into the bottom of the stair treads. This made a nice clean installation without any screw holes that you could see in the treads.

I threw the rubber stair treads on to the completed steps just so I could show you how it looks in place for the access port. Once I get the steps painted a nice gray color that match the other stairway I will install the rubber tread with double stick carpet tape to hold them securely in place. When you go up or down these steps you only have to duck under the upper edge of the four foot opening to come in or go out. It works great and is a great accessory to the shop and the garage when I need to move items in or out of either of the spaces. This access port will never be used on a daily basis so having to duck in or out of it is well worth it if I can have this kind of access to the shop when I need it.

Here the access panel has been reinstalled back into the wall to close up the opening once again. As you can see I still need to paint the basement wall from the stairway construction. I will also paint the access panel at the same time to make it blend in a lot better than the way it looks now with the Pink Panther logo on it. The steps I will not mounted to the wall as I thought it best to leave them as they are so that I can clean under the step or remove them to make more room in the basement when this access port is not being used. Either way this makes a great addition to the workshop and will come in handy in the coming years.